- Durable hard wearing

- Nonslip finish

- Excellent ponding water resistance

Uses

- Roof areas*

- Walkways

- Deck and balcony areas*

- Exposed roof surfaces for maintenance and access areas*

- *When used in conjunction with Gripset 38 as the base membrane layer

Substrates

- Concrete and masonry screeds fibre cement, compressed fibre cement and cement sheeting products

- Exterior grade plywood

- Hebel panels

Coverage

2 x coats at total minimum 1 litre/m2

Dry Times

Weatherproof: 72 hours

Colour

Grey

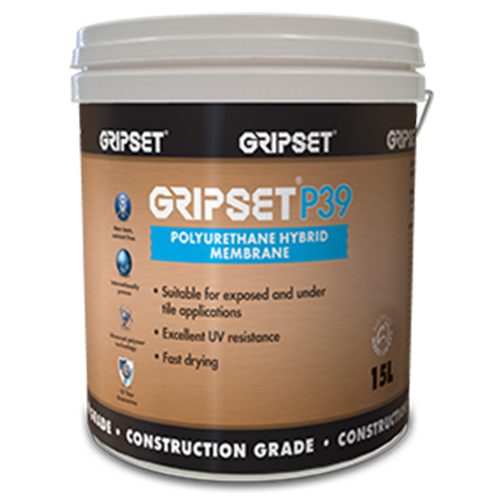

Packaging

15 litre pails